MCCC has produced and is donating hundreds of personal protection equipment products around the community.

MCCC has produced and is donating hundreds of personal protection equipment products around the community.

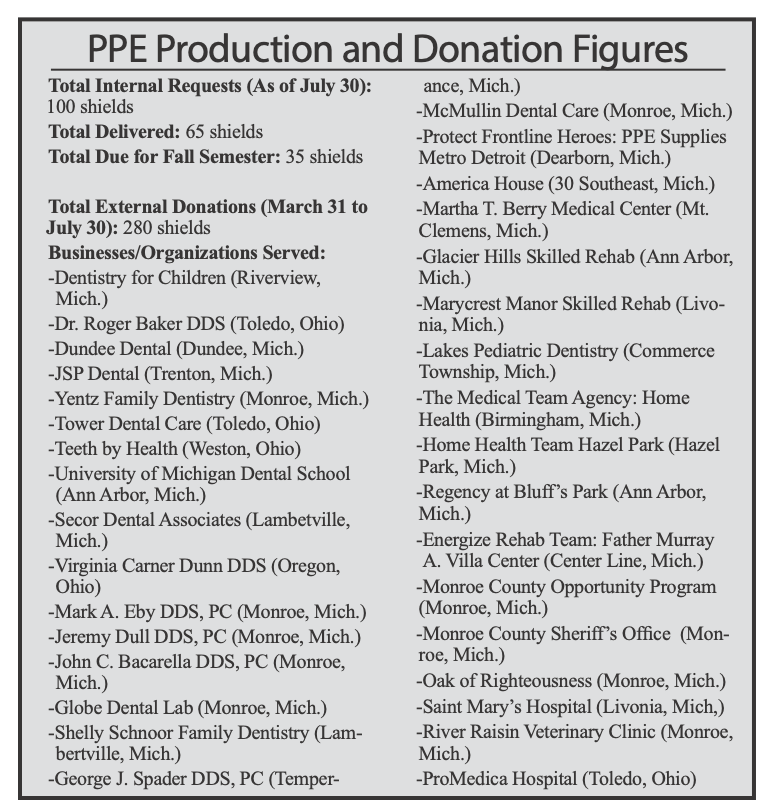

Since March, over 350 face shields have been produced, and distributed across campus and donated to over 30 organizations and businesses throughout the community and region.

Michael Reaume, ASET technician/Perkins technical specialist, who is in charge of PPE production, said production was at its highest in the spring and summer.

“The main reason for this is that PPE was largely ‘unobtainium’ back in April through June,” Reaume said. “As of right now, all of our current requests for shields here on campus have been fulfilled.”

At its current rate, the Makerspace can produce approximately 14 face shields every two days said Reaume.

In MCCC’s Makerspace, production of personal protection equipment, PPE, is completed using plastic filaments, 3D printers and a CNC laser.

While the majority of production consists of face shields, the PPE also includes hands-free door openers and face mask adjusters.

The primary recipients of face shields are dental practices and other medical institutions.

In addition to the equipment produced, isolation gowns, scrub caps, shoe covers and other PPE items have been purchased and donated, Reaume said.

The production of PPE has cost approximately $2,500 so far, said Parmeshwar Coomar, dean of Applied Science & Engineering Technology.

Despite the cost, the project has been entirely voluntary.

“There was no additional monetary incentive to do it,” Reaume said. “We just had the equipment to help out and wanted to see what we could do with it to make a difference.”